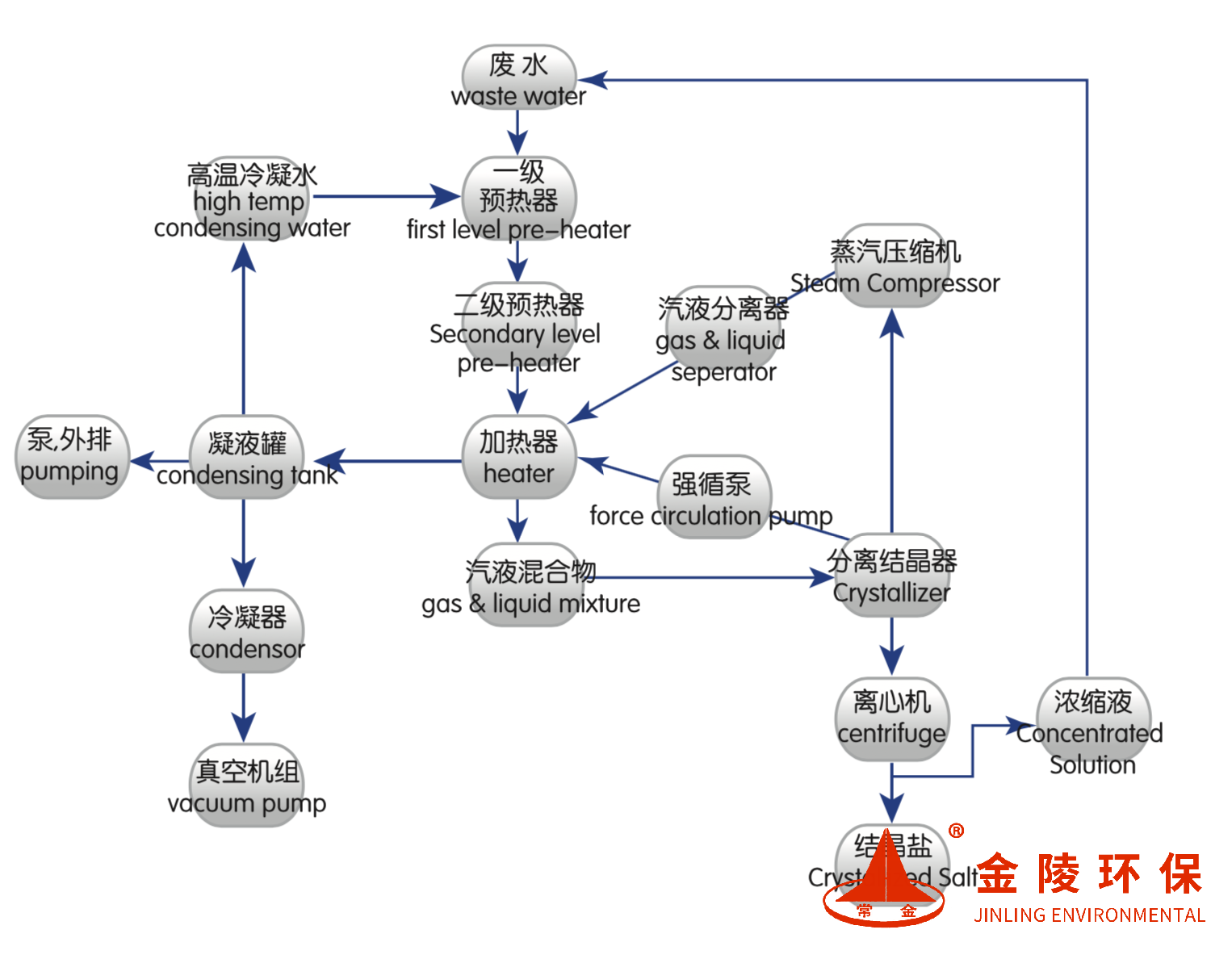

Principle

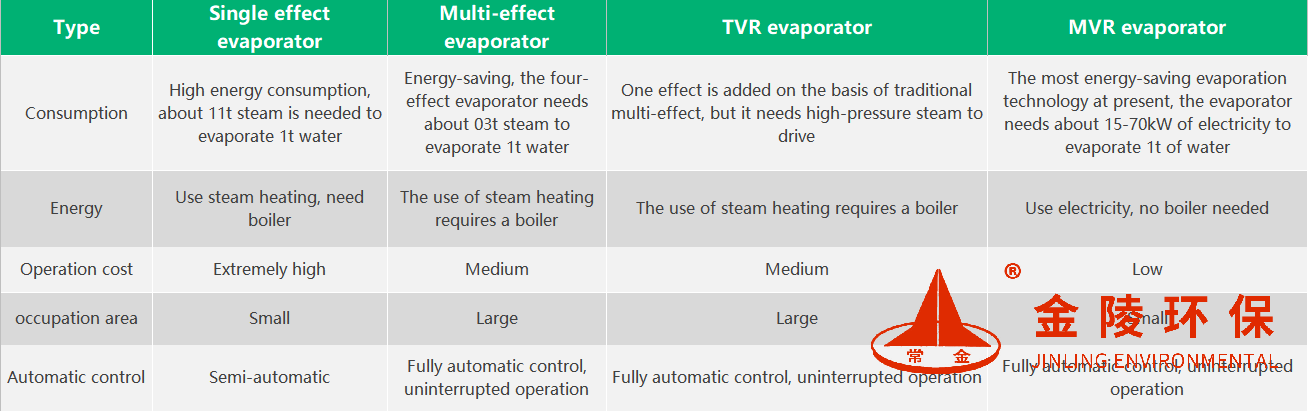

The MVR mechanical vapor recompression device uses the secondary steam generated in the evaporation system to work through the compressor to increase the steam pressure and enthalpy. This helps to circulate heating and evaporation, making full use of the residual heat of the condensed water of the secondary steam machine in the system, which has outstanding energy-saving effects. Aside from the use of fresh steam and waste heat raw material steam, no additional steam is required. The self-circulation of the evaporator is used to cause evaporation and concentration, which can save 70-90% of energy consumption. The system consists of a preheater, evaporative heat exchanger, separator and steam compressor.

Process diagram

Technical Parameter

Technical Paramete | |

Input capacity(t/h) | 5 |

Steam consumption(t/h) | 0.1(Saturated steam) |

Steam pressure(MPa) | 0.30(Absolute pressure) |

Secondary steam pressure(KPa) | 50/110 |

Secondary steam temperature (approx)(°C ) | 85/105 Vapor phase |

Liquid material temperature(°C ) | 92±2 |

Heat exchaner loss(%) | ~5.0% |

Evaporator circulation | Forced circulation |

Installation power(kw/h) | ~300 |

Technical Features

◆ For wastewater with high ammonia nitrogen and organic content, the pretreatment method

can be designed to enter the evaporator;

◆Jinling independently designed and developed a variety of concentrated mother liquor treatment systems to improve system stability and reduce system blockage;

◆Simple operation, low operating cost, and can be used in series with multi-stage evaporation;

◆ The heater, preheater and condenser tube sheets all use integral tube sheets to extend the service life of the equipment;

◆ Automatic control system, automatic feeding, automatic discharge of condensate;

◆The discharging device is separated to increase the discharging crystal content, and most of the crystals are obtained after separation, the mother liquor is less refluxed, and the heat energy to be re-consumed is lower, which is energy-saving and environmentally friendly;

◆The forced circulation evaporator has: high heat transfer coefficient, high evaporation intensity, efficient anti-stick wall formation and anti-pipe blockage, etc. It is especially suitable for materials that produce crystals during the evaporation process;

◆ The self-circulation system is adopted to keep the crystals and mother liquor circulating at all times to avoid blockage by crystal deposits.

Previous:没有了!