patented technology

Summary

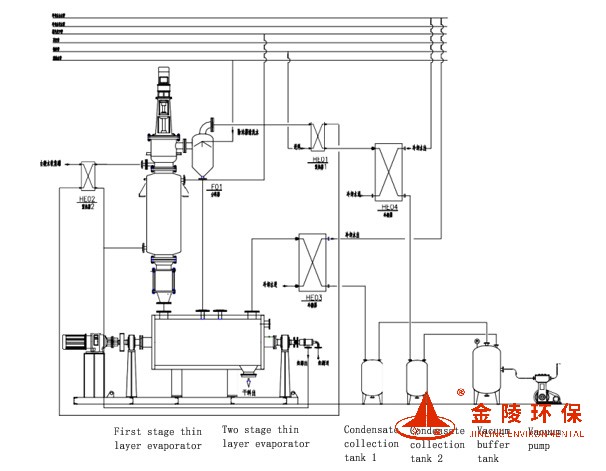

◆ The multi-effect thin-layer evaporator designed and developed by Jinling Company will combine the characteristics of industrial wastewater and organically combine the vertical thin-layer and horizontal thin-layer evaporation, which greatly improves the treatment capacity and concentration, and is suitable for various industrial wastewater processing

◆ This device is specialized in the comprehensive treatment of mother liquor with high salt and high organic matter. It effectively solves the shortcomings of previous treatment equipment such as MVR and multi-effect evaporation, pipe blockage, scaling, and unstable operation

◆ This device adopts a new type of low-temperature evaporation technology, which couples the first-level thin-layer evaporator and the second-level horizontal evaporation concentrator with an innovative structure to complete the liquid-liquid phase. This allows one to set the discharge concentration at will, and greatly reduce energy consumption. It also offers improved stability over previous models

◆ A wide range of adjustment of various parameters during operation, such as the concentration of the feed, the temperature, the thickness of the material film, the temperature of the heating medium, and the speed of the host machine can all change the crystallization efficiency of the salt in the liquid input. It can cause evaporation, concentration, solidification and different output of various materials

Principle

◆ Thin-layer evaporator is an evaporator that uses high-speed rotation to distribute liquid into a uniform film for evaporation or distillation. It consists of one or more jacketed heating cylinders and a high-speed rotating film scraping mechanism in the cylinder. The film scraping mechanism continuously scrapes the liquid into a uniformly thick film on the wall of the heating cylinder and moves downward, while the low boiling point components rise to evaporate and separate, and the heavy components are discharged from the bottom of the evaporator. The company’s innovative design combines the first-stage thin-layer evaporator and the second-stage horizontal thin-layer evaporator in series to extend the evaporation time and increase the discharge concentration